Trapezoid roof roll forming machine, also known as roof &wall panel roll former machine, is used for producing wall panel and roof. It could make steel sheets into required shapes and length. Metal trapezoidal roof is widely applied in commercial metal buildings and housing. Trapezoid roof forming machine features good appearance, high coverage, high strength and high automation. At the meantime, it has lower cost and longer lifetime. With good performance in operation, it works with little noise and is easy to maintain.The wall panel roller former is mainly composed of decoiler, roll former, cutting machine, PLC computer, hydraulic system and output table.

Trapezoid roof roll forming machine, also known as roof &wall panel roll former machine, is used for producing wall panel and roof. It could make steel sheets into required shapes and length. Metal trapezoidal roof is widely applied in commercial metal buildings and housing. Trapezoid roof forming machine features good appearance, high coverage, high strength and high automation. At the meantime, it has lower cost and longer lifetime. With good performance in operation, it works with little noise and is easy to maintain.The wall panel roller former is mainly composed of decoiler, roll former, cutting machine, PLC computer, hydraulic system and output table.

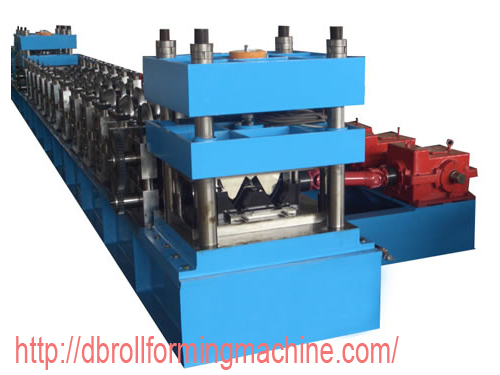

As a basic type of roll tile machine, C purlin roll forming machine, also known as C shape purlin forming machine, produces C purlin steel through cold rolling.

The formed C purlin steels possess metal of thin thickness, light weight, excellent section performance and high strength. Compared with the traditional channel steel, C purlin steel with the same strength can save 30% raw material. They are widely used as purlin and beam in steel structure building. In addition, they also can be used in mechanical light industries for manufacturing columns, beams, arms, etc.

Aided and optimized by computer, metal deck roll forming machine can be used to produce metal deck with high strength and big wavelength. As a CE certificated company, we provide metal deck roll forming machine and its subclass product—floor deck roll forming machine with superior quality and moderate price.

The metal decks out from metal deck roll forming machine are widely used for the floor flat, modern steel buildings, large factories and warehouses, etc. Comparing with other material in this field, metal deck could economize steel and cut down investment accordingly...

Tile forming machine also known as steel tile forming machine, is used for making steel tiles. The roof tile possesses good features of elegant style, light weight, strong strength, durability and easy installation. Certificated by CE standard, such steel tiles are widely used for building different architectures, such as villa, holiday village, gardening style factory, beauty spot, pavilion, exhibition center, etc...

High way guardrail forming machine, also known as motorway guard rail forming machine, is a special forming equipment for producing speedway guard rail. By adopting cold forming, cold punching, automatic stack, industrial automatic control system and precision machining technologies, the full working flow goes automatically with high efficiency. The full production line of high way guardrail roll forming machine is composed of decoiling system, leveling system, edge cutting system, head cutting system, punching system, roll forming system, post cutting system, automatic stacking system, hydraulic system and automatic control system...

Large span roll forming machine is used to produce the cover for arch-shaped building. Certificated by CE Authentication, it has been widely used in facilities, such as modern steel buildings, large factories and warehouses.

It can be debugged with little noise to realize a high performance in operation

1. Large span forming machines, totally controlled by PLC, are fairly easy to operate. They can work automatically only through inputting the related production data, such as product number, length and punching size, etc;

2. If users need to adjust the machine or something else, they must firstly stop the machine before carrying out relevant operations;

3. The maintenance is very easy. Regular lubrication for chain wheel, bearing and speed reducer of large span curving forming machines should be conducted carefully. And the forming rollers should be kept clean ...